Unloading and Loading Freight: Expert Safety Strategies to Protect Employees and Freight

Unloading and loading freight happens so often that workers and management can become complacent to the inherent dangers that exist in the process.

Unloading and loading freight is almost always under some sort of time constraint. This issue and tighter supply chain windows can exacerbate the problem and create an even more dangerous environment.

That can lead to increased accident rates and damaged freight, among other hindrances to your bottom line.

Below, we’ll cover some essential best practices for warehouse loading and unloading procedures to ensure safety and outline efficient systems that get the freight where it needs to go fast.

The Importance of Unloading and Loading Safety Protocols

Unloading and loading freight correctly and with the correct safety protocols simply makes for good business. If your business is touching freight in any way, you have deadlines and customers waiting on the other end. Loading and unloading trucks safely and efficiently is vital to your business’s success.

But beyond that, there are other benefits as well.

Employee Safety

Poor employee safety or workplace accidents are incredibly costly for companies. Not only are there the initial costs of the injury and related expenses, but the costs can pile up even after an accident. A company with a poor safety record will have trouble attracting new talent, and in today’s competitive hiring market, no business needs extra hiring stresses.

Beyond that, insurance premiums can increase, and levy regulatory fines if the company does not follow safety protocols.

Reduced Damage

Improving your unloading and loading procedures also reduces damage to incoming or outgoing freight. Pallets or boxes not correctly secured or checked when leaving can topple during transport. That leads to damage and can even create an accident on the road.

Damaged freight is wasted money. So reductions here have immediate cost benefits.

Reduced Liability

Every business needs to deal with insurance premiums. Accidents or damage to equipment and infrastructure from improper loading and unloading can increase premiums or even cause it to become too difficult to secure insurance in some cases.

Proper truck loading and unloading procedures help to mitigate these risks and keep premiums in check.

Increased Efficiency and Lower Overall Costs

Finally, you want your unloading and loading to be as efficient as possible because it streamlines your entire process. Whether bringing in goods for production or sending goods out the door to a customer, the faster and more efficient, the better.

With tight safety protocols, you can operate fast and without accidents.

Loading and Unloading: Best Practices

In this section, we’ll go over critical best practices that will help improve your truck loading and unloading area and keep everyone safe and working efficiently.

Centralized Warehouse Management

There needs to be a centralized system to keep tabs on all activity within the warehouse and dock area. Many warehouse management software (WMS) programs are available now, which makes this task much easier for dock managers and other employees.

These warehouse management solutions can help:

- Master controls for dock safety equipment

- Freight dimensioning to increase safety and efficiency while loading freight

- Dock management software that can be tied to sensors and other data tools to keep managers informed at all times.

- Layout and space planning to increase efficiency and safety.

Use Trailer Restraints Instead of Chocks

Trailers inadvertently leaving the dock either through miscommunication or simply rolling away is a common cause of injury and accidents when unloading a truck. Use trailer restraints that securely lock the trailer to the dock until a central control panel releases it.

Some docks still use chocks, which are dangerous to install and remove. Replace these outdated chocks with restraints to increase safety and overall efficiency when warehouse truck loading or unloading.

Use Barrier Gates

Barrier gates are common in almost any industrial setting, and loading and unloading docks should be no different.

Install barrier gates to prevent falls from ledges or to block off areas where machinery like forklifts operate. Keeping people out of dangerous areas in the first place is the best way to prevent accidents.

Hydraulic Dock Levelers

Differences in height at different dock areas are where many trip and fall accidents occur when workers unload the freight. Using hydraulic dock levelers immediately bridges the uneven gap between trailers and the dock.

These can easily be used with the press of a button. Once installed, encourage workers to use them more frequently than manual versions, which employees often ignore due to the extra work involved when unloading freight.

Employee Training

No safety system can overcome poor training or a lack of training. All employees must be taught the proper safety procedures around unloading and loading areas. That means both in written form and in-person training.

Also, make sure there is an identified team lead for safety issues that employees can contact if safety issues are detected. Communication is vital to safety, and employees should know they can contact someone and resolve the issue quickly and without pushback.

Creating a safety culture ensures protocols are in place and safety lapses are quickly identified before an accident occurs.

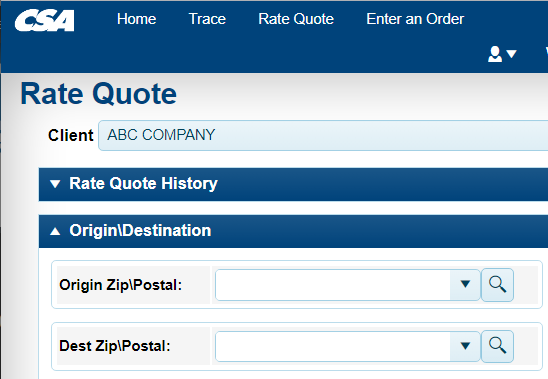

Get Help With Transportation and Logistics with CSA

If you need assistance with logistics or shipping freight from Canada to the US, let CSA be your trusted transportation partner.

We have regional expertise and a national network that can help improve your logistics and get your freight where it needs to go fast and without worry.

Contact CSA today and learn how to improve your business with our innovative shipping solutions.